Equipment Overview

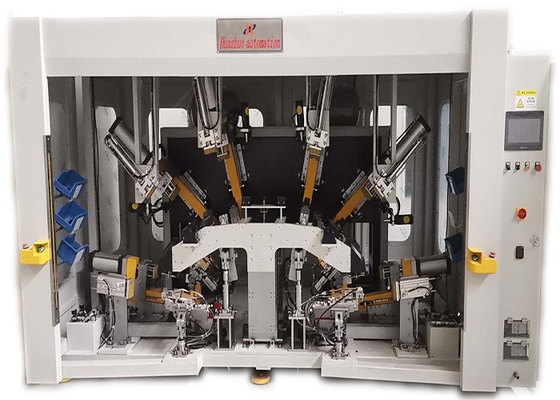

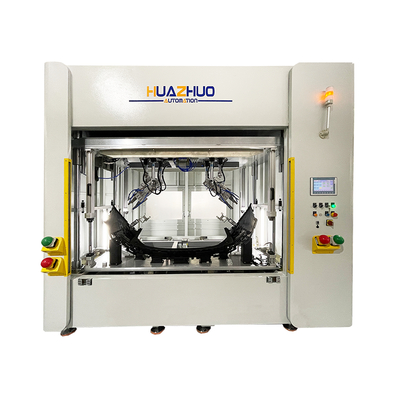

Huazhuo’s High-Precision Ultrasonic Welding Machine for Automotive Rear Bumper delivers cutting-edge automation tailored for welding plastic automotive bumper components. Engineered with servo-driven precision and integrated quality assurance systems, this machine enhances welding accuracy, reduces manual labor, and ensures consistent production output for OEMs and Tier 1 automotive suppliers.

This equipment is specially designed for welding thermoplastic materials commonly used in automotive bumpers, such as PP, PA, ABS, and their blends, offering high reliability and productivity in rear bumper assembly lines.

Key Features

1. Ultrasonic Welding Precision

Welding positional accuracy within ±0.03mm

Optimized energy control for strong, defect-free welds

Suitable for diverse thermoplastic bumper materials (PP, PA, ABS, EPDM, PPO)

2. Advanced Quality Assurance

Real-time welding parameter monitoring (force, amplitude, time)

Integrated vision system inspects weld quality and alignment

Poka-yoke and automated fault detection to prevent defective parts

3. Automation & Industry 4.0 Ready

Siemens PLC control with intuitive 12” touchscreen HMI

Supports remote diagnostics and software updates

4. Robust Safety Features

Safety light curtains, emergency stop, and interlock systems

Ergonomic design for operator comfort and ease of use

Application Scenarios

Designed for automotive manufacturing and Tier 1/Tier 2 suppliers focusing on:

Rear bumper welding for passenger cars and commercial vehicles

Plastic bumper assemblies including brackets and reinforcement components

E-mobility bumpers tailored for electric vehicles

Technical Specifications

|

Item Name

|

High-Precision Ultrasonic Welding Machine for Automotive Rear Bumper

|

|

Voltage

|

380V

|

|

Motor

|

Servo Motor

|

|

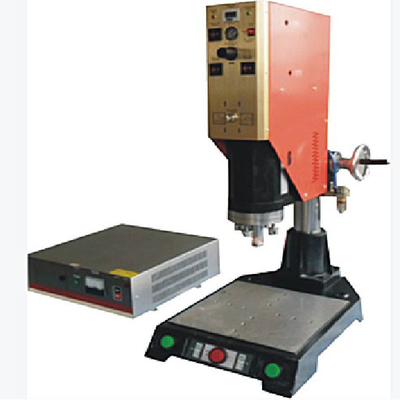

Welding Type

|

Ultrasonic Welding

|

|

Welding Time Range

|

0.1s – 5s

|

|

Product Name

|

Automotive Rear Bumper

|

|

Product Material

|

PP+EPDM-TD20

|

|

Control System

|

PLC + Touchscreen

|

|

Safety Protection

|

Light Curtains, Interlocks, Emergency Stop

|

|

Ambient Temperature

|

0℃~45℃

|

|

Machine/Mold Weight

|

Customized

|

|

Machine/Mould Size

|

Customized

|

Why Choose Huazhuo?

20,000 m² R&D & manufacturing facility in China

Over 12 years of expertise in automotive non-standard automation

Trusted partner for OEMs and Tier 1 suppliers worldwide

Comprehensive after-sales support with remote troubleshooting and on-site training

After-Sales Service

1-year warranty on main components

Remote technical assistance via video call and software tools

Optional on-site commissioning and operator training

Fast replacement parts delivery

Related Products

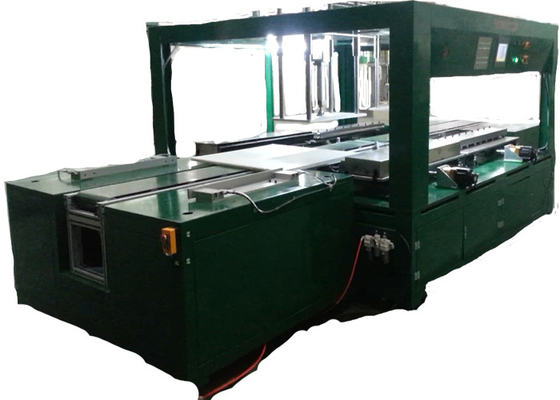

Bumper Hole-Punching & Welding Integrated Machine

Robotic Ultrasonic Welding Systems for automotive plastic parts

Hot Riveting Machines for automotive components bonding

Hot Plate Welding Machines for large plastic assemblies

Automated Clip Insertion and Screw Tightening Machines

Automotive Interior Wrapping and Edging Equipment

Complete Automotive Door Panel Assembly Lines

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!