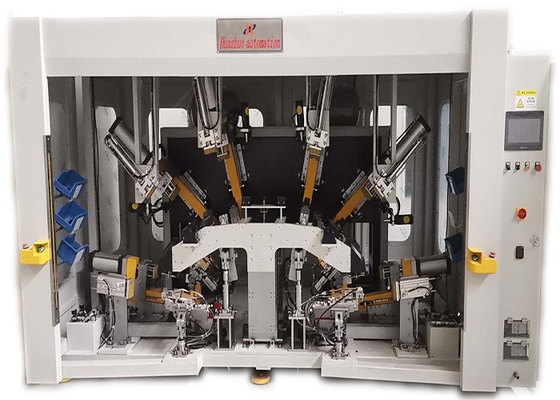

High-efficiency Covering & Laminating Machine for Automotive Center Console Trim

One-stop wrapping solution for automotive interior trim components

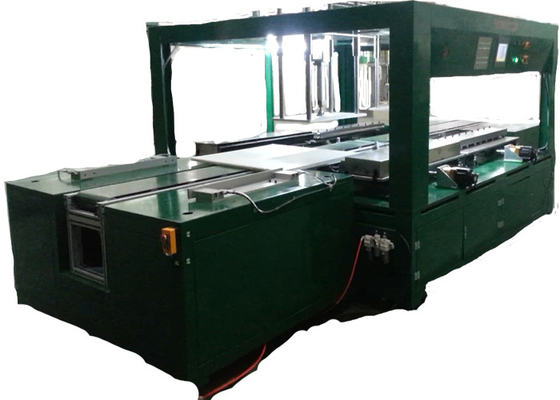

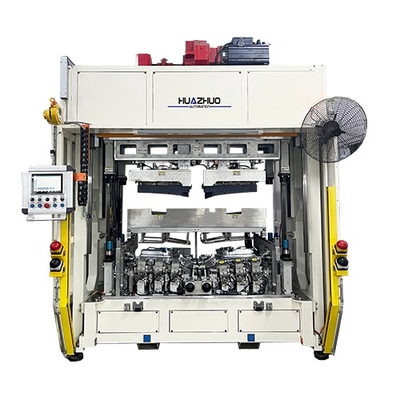

This high-efficiency covering and laminating machine is tailored for the automotive interior industry, enabling automatic wrapping of plastic parts such as center consoles, dashboard panels, door trims, and armrests. The machine combines heating, pressing, laminating, and edge folding in a single automated cycle to ensure high consistency, premium surface finish, and strong bonding—suitable for OEM and Tier 1 production standards.

Key Features

- Integrated Process: Heating, laminating, and edge folding completed in one machine

- Servo Control System: Ensures precision and repeatability for 3D curved parts

- Material Compatibility: Supports PU leather, PVC film, microfiber, Alcantara, fabric, ABS/PC substrates

- Modular Molds: Fast changeover between different part shapes and sizes

- User-friendly Interface: Intuitive PLC touch screen for parameter adjustment and recipe storage

- Safety Protection: Light curtain and emergency stop system included

Production Workflow

Typical Applications

Automotive center consoles

Instrument panel upper/lower covers

Door panel decorative areas

Glove box lids and armrests

HVAC panel covers and trim bezels

Also applicable to:

✅ EV interiors ✅ Luxury car trim ✅ Soft-skin appliance panels

Technical Specifications (Customizable)

|

Item Name

|

High-efficiency Covering & Laminating Machine for Automotive Center Console Trim

|

|

Voltage

|

380V

|

|

Controlling System

|

PLC

|

|

Ambient Temperature

|

-10℃~50℃

|

|

Machine/Mold Weight

|

Customized

|

|

Machine/Mould Size

|

Customized

|

|

Safety Protection

|

Light Curtain

|

|

Input Air Pressure

|

≥6bar

|

|

Compatible Materials

|

PU, PVC, microfiber, ABS/PC, TPO

|

Advantages for Production Line

Consistency: Eliminates surface defects like wrinkles and bubbles

Efficiency: Cycle time 30–60s/part depending on size and material

Cost Saving: Replaces manual wrapping, reduces labor and scrap

Scalability: Supports high-mix, low-volume or large-scale mass production

After-Sales & Support

1.One-year warranty service

2.Online support, Video technical support

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!