Product Overview

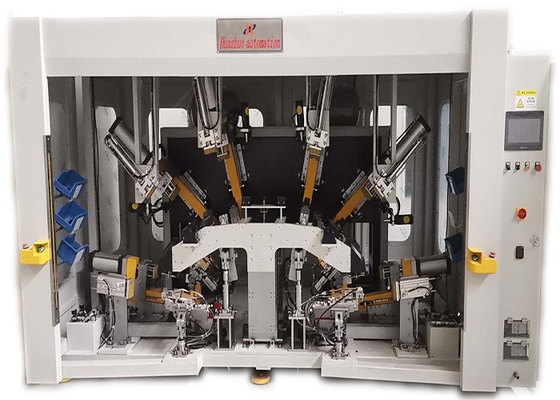

This system is a dedicated clip insertion automation solution for automotive door panel assembly, using a single 6-axis Yaskawa robot. It integrates intelligent clip feeding, servo/pneumatic insertion, CCD detection, and safety protection—all in a space-efficient structure. Designed for Tier 1 suppliers and OEM plants, this machine ensures accurate, fast, and traceable clip installation with reduced labor and higher production consistency.

Working Principle

Clips are automatically fed via a customized blow-feed system and picked by the robotic arm. The robot inserts each clip into the specified location with controlled force and angle. Vision systems confirm part presence and clip installation accuracy, while sensors prevent misfeeds or omissions. A form-based fixture** ensures high alignment precision during loading.

Application Scenarios

Tailored for plastic and composite parts requiring precise clip fastening, especially:

lFront & rear door panels

lInterior trims with plastic or metal clips

lComponents with variant L/R models

lSmall- to medium-batch automotive assembly stations

Technical Specifications

|

Item Name

|

Single 6-Axis Robot Clip Insertion Equipment

|

|

Voltage

|

380V

|

|

Robots

|

6-axis

|

|

Application

|

Automotive Door Panel Clip Assembly,etc

|

|

Feed System

|

Blow-feed + Vibratory Bowl

|

|

Clip Capacity

|

~2,100 Clips Per Refill

|

|

Clip Feeding

|

Vibratory Bowl + Blow-Feed, ~2,100 Clips Per Load

|

|

Clip Type

|

Plastic Clips, Snap Locks

|

|

CCD Vision

|

CCD Camera + Sensors Verifies Part Position, Clip Orientation, And Seating

|

|

Cycle Time

|

~2.5 s Per Clip

|

|

Fixture Type

|

Form-fit Positioning For Internal And External Trim Parts

|

|

Control System

|

Siemens/Mitsubishi PLC + Touch HMI

|

|

Ambient Temperature

|

-10℃~50℃

|

|

Machine/Mold Weight

|

Customized

|

|

Machine/Mould Size

|

Customized

|

|

Safety Protection

|

Light Curtains, Interlocks, Emergency Stop

|

After‑Sales Service

1-Year Quality Warranty

Remote Technical Support (via video and software)

On-site Commissioning & Operator Training (optional)

Quick Replacement of Critical Parts

Why Choose Huazhuo Single-Robot Systems?

Huazhuo Group, based in Suzhou, China since 2012, specializes in the design and manufacturing of custom non-standard plastic welding and fastening automation. Our equipment is used in production lines of global automotive OEMs and component suppliers.

lCompact & Flexible: Ideal for focused workstations or cell-based layouts

lHigh Precision: Vision-guided insertion with verified force control

lCustom-Fit: Built to match your door panel structure and clip specs

lIndustry Ready: Supports Siemens/Mitsubishi PLC, Yaskawa robots, modular tooling

Related Automation Systems

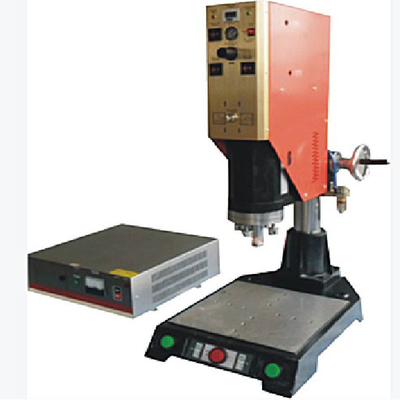

Ultrasonic Plastic Welding Machines

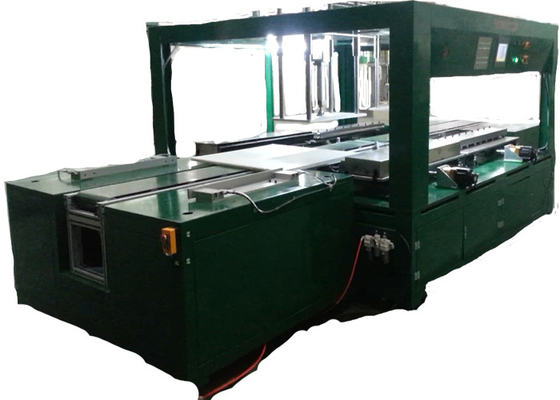

Servo Hot-Plate Welding Machine

Automated Riveting & Heat-Staking Plastic Welding System

Trim Laminating & Covering Equipment

Automated Screw Tightening Machine

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!